Chemicals

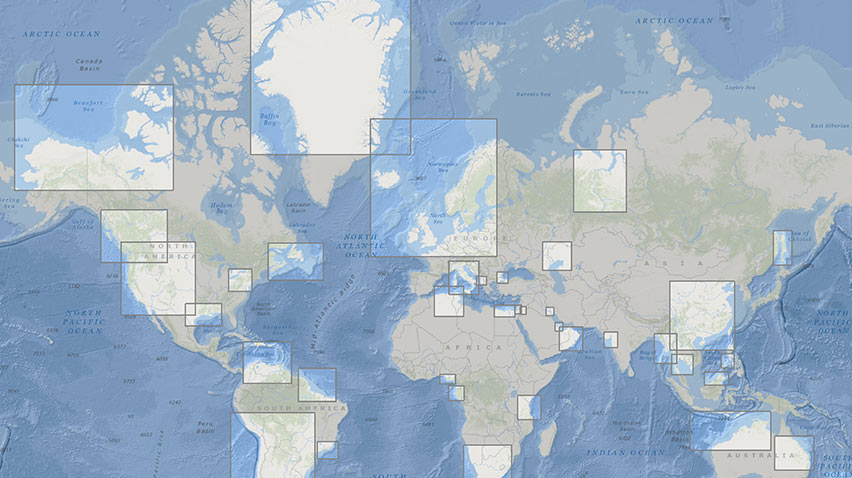

We have more than 80 years of experience in the chemicals industry and produce and supply 17 million tonnes per annum (mtpa) of chemicals to about 1,000 large industrial customers worldwide. Our plants produce a range of base and intermediate chemicals. We have the capacity to produce over 6 mtpa of ethylene.

Our products are used to make numerous everyday items, from clothing and cars to detergents and bicycle helmets.

Over many decades, we have developed proprietary technologies, processes and catalysts that enable us to compete strongly in our core petrochemical markets. For example, Shell Chemicals has launched Shell gas-to-liquids (GTL) fluids and solvents, which are high-purity paraffinic fluids and solvents made from GTL products manufactured at our Pearl facility in Qatar. We are the first company to offer a range of natural gas-based fluids and solvents to the chemicals industry worldwide.

We will continue to focus on increasing synergies between our petrochemical plants, refineries, Integrated Gas and Upstream businesses to increase supplies of the best available feedstock to our facilities.

Chemicals is now a growth priority for Shell. Petrochemicals is the fastest growing hydrocarbon demand sector, with annual growth of 3.7% over the last 10 years, and we expect this to continue. Shell’s Chemicals strategy focuses on activities with a clear competitive advantage. We optimise returns from using different feedstocks, invest in our existing first-class footprint, and continue to focus on enhancing our customer relationships and service. With a competitive edge in chemical feedstocks, underpinned by a strong product portfolio and proprietary Shell technology, the business is entering a new period of growth.

Our Chemicals strategy is based on investment at existing sites to increase capacity, improve efficiency and integration, and to strengthen our feedstock sources. Securing new integrated growth projects and developing technologies to convert gas into chemicals are also critical strategy components.

In 2016, we announced final investment decisions (FID) on two major projects.

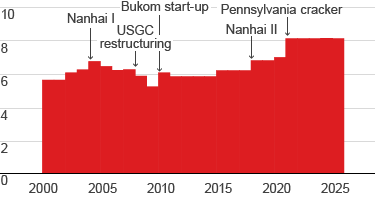

In China, we announced the FID to expand our joint venture (JV) with China National Offshore Oil Corporation (CNOOC) in Huizhou, Guangdong Province, which includes the Nanhai petrochemicals complex. The expansion includes the ongoing construction of a new ethylene cracker and ethylene derivatives units, which are expected to increase ethylene capacity by more than 1 mtpa when completed.

In the USA, we announced the FID on a petrochemicals complex in Pennsylvania. The site will have a 1.6-mtpa polyethylene capacity, using ethane from the lowest-cost shale gas basin in North America to produce polyethylene at world scale. Main construction is expected to start by 2018, with commercial production beginning early in the next decade.

In January 2017, we agreed to sell our 50% interest in the SADAF petrochemicals joint venture with SABIC in Saudi Arabia. In 2016, the joint venture’s production was around 4 million tonnes. The transaction is expected to be completed in 2017.

We will continue to focus on selective and prudent investments with a competitive advantage to ensure profitable growth in the future.

Ethylene capacity

Million metric tonnes

Operator checks product label print quality at the Shell Nangang Lubricant Oil Blending Plant, China.